- Product category

-

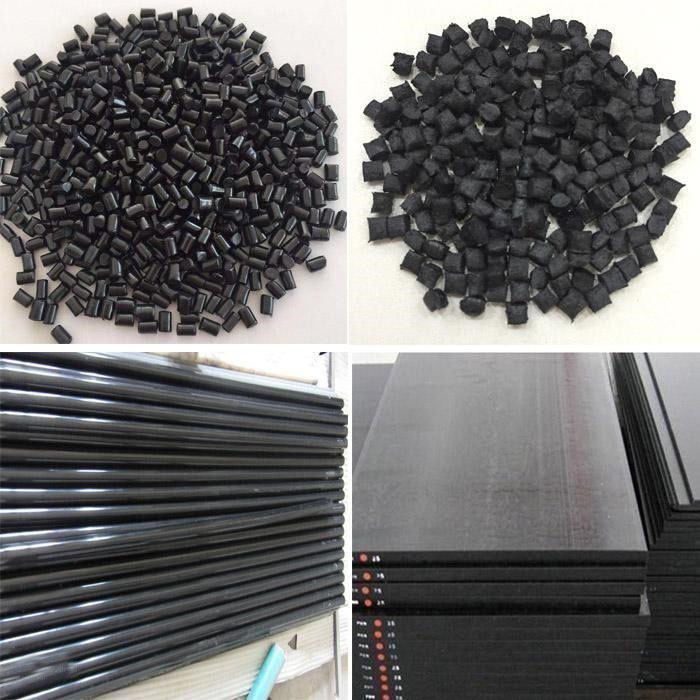

Product name:PEEK CNT Compound

Product model:PEEK CNT CA

Product brand:INCHR

Product specification:10E6~10E9 Ohms

Product description:PEEK CNT CA 2093

The CA series is a ESD PEEK CNT compound which is widely used in semiconductors, automotive and aviation, automotive fuel pumps and gearboxes. It helps the equipment to reduce weight, reduce noise, improve the service life of wear-resistant parts, and reduce or even avoid the use of lubricating oil.It is a special polymer material compounded of polymer resin and special conductive materials such as CNT.

Main Properties

Product information

Material ID

>ESD PEEK CNT <

Process

Extrusion/Injection Molding

Physical property

Standard

Value

Unit

Density

ISO 1183

1.39

g/cm³

Shrinkage TD

ISO 294-4

0.45

%

Shrinkage MD

ISO 294-4

0.1

%

Mechanical behavior

Standard

Value

Unit

Tensile Modulus

ISO 527-2

28300

MPa

Tensile Strength

ISO 527-2

265

MPa

Elongation

ISO 527-2

1.7

%

Flexural Strength

ISO 178

380

MPa

Flexural Modulus

ISO 178

24000

MPa

Charpy Un-notch Impact Strength 23 ℃

ISO 179/1U

46

KJ/m²

Izod Notch Impact 23°C

ISO 180-A

11

KJ/m²

Thermal

Standard

Value

Unit

HDT 1.80MPa

ISO 75-2/Af

336

°C

Melting Temperature

ISO 11357-3

344

°C

Electrical properties

Standard

Value

Unit

Surface Resistivity

10E+3~10E+6

Ohms

Extrusion processing

Value

Unit

Dry Temperature

150~160

°C

Dry Time

2~4

hr

Mould Temperature

130~200

°C

Cylinder temperature

350~400

°C

Processing Temperature

360~400

°C

Recommended Process Guidance For PEEK CNT :

1. Drying: the granular PEEK polymer generally absorbs 0.5%w / w atmospheric moisture. In order to obtain the best effect, it should be dried until the moisture is less than 0.02%w / w. PEEK CNT may be placed in an air circulating furnace for at least 150℃ for 3 hours or at 160℃ for 2 hours. If dried in a drying box, the thickness of the raw materials in the pallet shall not exceed 25mm and prevent contamination.

2.Recycling: The remaining material can be recycled and injected into the pure material. It is recommended that recycled materials without fillings should not exceed 30% of the total weight, and recycled mixture with fillings should not exceed 10% of the total weight.

3. Thermal stability: If the equipment is stopped during the melting process, and the polymer residence time is not more than 1 hour, then there is no obvious degradation of the material at the temperature of 370℃. However, if the downtime exceeds 1 hour, the temperature of the material cylinder should be reduced to 340℃. At this temperature, the PEEK CNT can remain stable for several hours, and the temperature of the material cylinder must be increased when continuing processing. If the downtime exceeds 3 hours, the material cylinder should be cleaned. It can be cleaned with materials that maintain stable performance at 380℃, such as polyethersulfone or polyetherimide, or with polyethylene with low MFI.

4. Extruder machine: the melting point of the polymer is 343℃, which can be applied to the traditional machine that can maintain the melt temperature at 360-400℃.

5. Cylinder capacity: Because the processing temperature of PEEK CNT is very high, the residence time of the material must be as short as possible. The ideal material barrel capacity is at 2-5 times the total ejection weight.

6. Nozzle and lock system: The melting point of the polymer is very high. If the temperature drops below 343℃, the melt will solidify quickly. Therefore, it is necessary to install a large enough heater in the nozzle to prevent the cooling of "extrusion mold cooling".

7. Screw: The minimum value of the screw length ratio L / D is 16:1, but the L / D ratio between 18:1 and 24:1 should be preferred.

8. Extrusion pressure: the general injection pressure of 8-20 MPa.

9. Extruding speed: medium speed.

10. Screw speed: the general screw speed is 10-20rpm. For the reinforcement level, it is recommended to use a lower screw speed.Next:ESD M30AN