- Product category

-

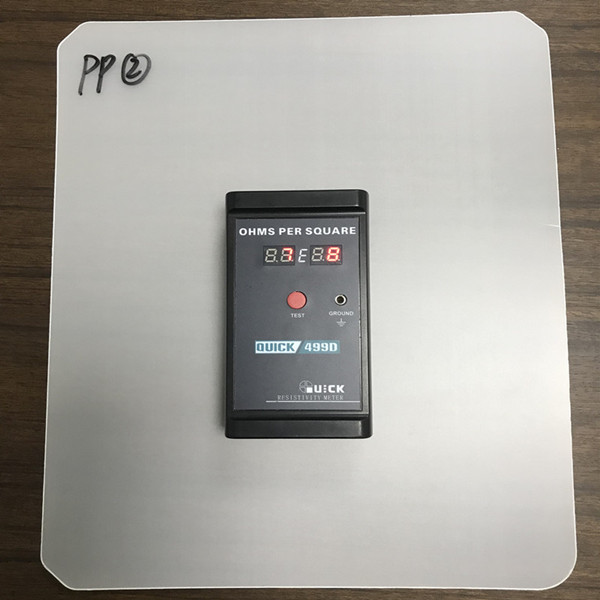

Product name:PP Concentrate

Product model:Antistatic Agent In Polymer PP

Product brand:INCHR

Product description:Antistatic Agents In Polymer PP

Introduction of antistatic agents in polymers

Permanent antistatic agent in polymer is suitable for antistatic treatment of polymer PP, PE, PET,PBT,PA,PC,ABS and other polymers. It has good compatibility, no precipitation. It is recommended to add 10-30%, and the surface resistance of end-product can achieve 10E7-10E11 Ω.

The series of antistatic agents in polymer can be used in plastic flexible packaging, containers,sheet ,film , foam products, electronic pallets, electrical components, material modification, antistatic masterbatch, agricultural shed film, coal mine underground supplies and other products and industries; suitable for injection molding, extrusion Extrusion, blow molding, rotational molding,coating molding, physical/chemical foaming, molding and other process types.

The following chart shows the grades of antistatic agents and polymer types.

Polymer Based On

Grade Name

Addition Level

(wt%)

Surface Resitivity

(Ohms/sq)

ABS antistatic agent

ABS 600AN

8 to 25%

10^7 to 10^11

PC antistatic agent

PC 700AN

15 to 25%

10^8 to 10^11

TPU antistatic agent

TPU 90AN

10 to 25%

10^8 to 10^10

Nylon antistatic agent

PA 300AN

10 to 25%

10^7 to 10^10

HDPE antistatic agent

PE 80AN

10 to 25%

10^7 to 10^11

PBT antistatic agent

PBT W4AN

8 to 25%

10^7 to 10^10

POM antistatic agent

POM 55AN

8 to 25%

10^7 to 10^10

TPEE antistatic agent

TPEE 40AN

10 to 30%

10^6 to 10^10

PP antistatic agent

PP 20AN

10 to 45%

10^7 to 10^10

PVC antistatic agent

PVC 50AN

10 to 20%

10^9 to 10^11

TPE antistatic agent

PO TR1AN

10 to 20%

10^7 to 10^11

Application for antistatic agents in polymer PP

PP 20AN is designed for PP or PE extrusion which can reach 10E9-10E11Ω at dosage 18% Long-Term Protection.For Single Layer ,we recommend that ratio of Homo PP Co and PP is 80:20 ,to add PP 20AN dosage 26% achieve surface resistivity 10^10 ~10^11 ohms, thickness 0.35 to 0.55mm;For three layer, ratio of Homo Homo-PP and PP 20AN is 55:45.it achieves 10^9 ~10^11 ohms.

Antistatic PP sheet not only has transparency, good barrier properties, low density, non-toxic and hygienic, but also can be recycled. It does not produce toxic and harmful gases when heated or burned, does not harm human health, and does not corrode equipment. Antistatic agents in polymer is a new type of material. Green and environmentally friendly packaging materials. After antistatic agent in polymer incorporates into a material matrix PP,the antistatic PP sheets can be made into various products through secondary processing such as thermoforming, and are mainly used for semi-conductor transportation,chip package , medical equipment, etc. For example, it can be processed into IC trays.

Why should we need permanent antistatic agent in polymers for long-term protection?

Static electricity accumulation is very common in daily life:

*Smartphone manufacturing, handling and repair.

*New energy vehicle manufacturing.

*Semiconductor transportation.

*Electronic applications.

*Packaging of dusty organic materials.

*Aviation sector.*Clean-rooms.

*Fires caused by static discharge in fuel lines.

*Inflammable and explosive environments like healthcare, operating rooms, and paint shops

The dissipation of static charge relies on inherently dissipative polymers(IDP).Most antistatic agents in polymer utilize charge structures to dissipate the charge built up on surface of the material.Pre:TPU ConcentrateNext:HDPE Concentrate