- Product category

-

Product name:Conductive Masterbatch

Product model:Conductive Concentrate Compound

Product brand:INCHR

Product description:INCHR Conductive Masterbatch Grades

Solutions for electro-static discharge and EMI shielding

Conductive masterbatch is a material that plays an important role in the electronic field and has high conductive properties and conductive stability. In current electronic equipment, conductive masterbatch is widely used in electrical equipment such as batteries, wires, and integrated circuits. The purpose of this survey is to understand the market demand, product characteristics and industry development trends of conductive masterbatch.

First of all, through communication and interviews with a number of electronics industry-related companies, we learned that the market demand for conductive masterbatch in the electronics industry is very strong. Due to the continuous popularization and upgrading of electronic equipment, the demand for conductive masterbatch is increasing year by year. Especially in the fields of new energy vehicles, smartphones, batteries, etc., the application of conductive masterbatch is rapidly expanding.

Secondly, conductive masterbatch has high conductive properties and conductive stability. Its conductive properties can determine the conductive efficiency of electronic equipment, and its conductive stability can ensure long-term stable operation of electronic equipment. Compared with traditional conductive materials, conductive masterbatch not only has better conductivity, but also has better stability under environmental conditions such as temperature changes and humidity changes, which can effectively improve the performance and work efficiency of electronic equipment.

Carbon black grade is one of the most versatile functional fillers for ESD plastics. It always providing electrical conductivity to conductive masterbatch for ESD protection, carbon blacks function as a moderately low cost pigment, producing various shades of black on the end product.It can be combined with a variety of carrier resins,such as ABS ,HIPS ,PP,PE,POM ,PET and PA,to produce the conductive compound.

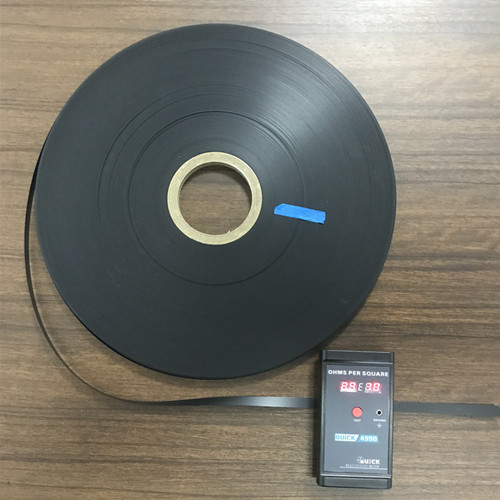

About selection of conductive carbon black,to choose the correct conductive carbon black for conductive masterbatch,good dispersion is the first choice. The conductive carbon black with the best performance can be selected based on the specific application conditions of the product. For example, in film applications, the dispersion and particle size of conductive carbon black are more important. The larger the specific surface area, the smaller the size of the carbon black particles. The more particles there are in a unit volume, and the easier it is to contact each other to form a network path. Therefore, the larger the specific surface area, the better the conductivity. For thick-walled pipes, choosing conductive carbon black is relatively easy.

Carbon Nanotube grade and graphene grade can be used in high purity applications and have virtually no effect on shrinkage or mechanical properties compare to carbon black type conductive masterbatch.

PP Conductive Masterbatch

PP CNT2003 is a high conductivity plastic masterbatch, which is prepared by adding 20wt% CNTs and copolymerized PP as the base material. It is suitable for all kinds of applications that need conductive and antistatic (ESD) properties with PP resin.

The PP conductive masterbatch offers excellent electrical properties by having a good carbon nanotube or carbon black dispersion. It can be used as a concentrate at a dosage of 10-50%.

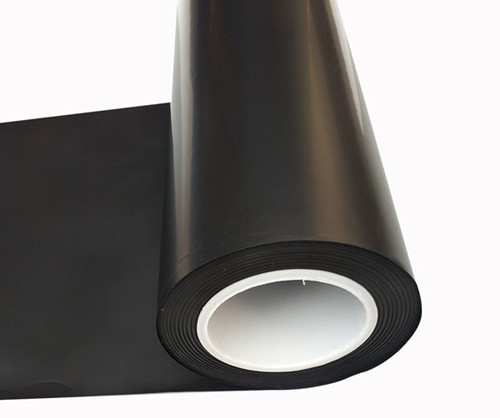

This compound is also used for co-extruded conductive wire,single -layer or multiple-layer conductive film based on PP resin.

PC Conductive Masterbatch

PC CNT1500 is a conductive masterbatch with 15wt% MWCNTs. It is suitable for all kinds of applications that need conductive and antistatic properties.

PC CNT1508 has excellent electrical conductivity, which is better than the plastic masterbatch with carbon black and carbon fiber at the same proportion.

This conductive masterbatch offers higher stiffness and heat deflection properties than similar polystyrene conductive compounds.

PA6 Conductive Masterbatch

PA6 CNT1508 is a conductivie masterbatch prepared by adding 15wt% multi walled carbon nanotubes and PA6 as the base material. It is suitable for injection and extrusion process.

This conductive compound is especially suitable for flexible injection molding and profile extrusion applications.

PS Conductive Masterbatch

PS CNT1505 is a conductive masterbatch made of HIPS and 15wt% MWCNTs.

This conductive masterbatch is developed for the use in highly flexible items and offers very high flexural fatigue strength and a high elongation at break.

It 's suitable for extruded conductive PS sheets.According to the target resistance value of the sheet,add an appropriate amount of conductive masterbatch concentrate,During customers' application cases,dosage 30% can achieve 10^6 to 10^8 Ohms.

Packaging And Storage Instructions

All grades are delivered dried in sealed packaging (25 kg bags) ready to be processed.

All Conductive masterbatchs can be stored in its original packaging for at least 12 months without losing its properties.

Pre:Conductive PETNext:Conductive PP