- Product category

-

Product name:Nylon Concentrate

Product model: Antistatic Agent For Nylon

Product brand:INCHR

Product description:Antistatic Agent For Plastics

Antistatic Masterbatch For Nylon Polymer

Selection of antistatic agent for plastics

Antistatic agent for plastic is designed to control static charges at various stages of processing, or to provide long-term ESD protection based on the application. However, finding the suitable antistatic agent plastic for your product among the various additives available in the market can be a challenging assignment!

A comprehensive review of important aspects related to antistatic agents and their chemical component, as well as factors affecting the selection of antistatic agents for plastic, including their compatibility with various polymers such as polyolefins, polyesters, polyamides, and alloys.

Regular plastics are insulating materials subjected to electrostatic build-up and discharge depending on the surface resistivity of the part. Plastics such as PP ,PE,PVC,ABS,PC,PA,POM,TPE,they tend to collect electrons and become negatively charged.For PP,PE,PVC,ABS resin ,we highly recommend polyolefins type antistatic agent,for TPE,TPU resin,polyesters type is preferable,for PA and POM resin,polyamides is the most suitable,because engineering plastics have higher meting point.

The dissipation of the static relies on creating conditions for unwanted electrons to move away from the end-product surface. Most Antistatic agents for plastic make use of charge structures to release the material accumulated charge.

Introduction Of Polyamide Copolymer 300AN

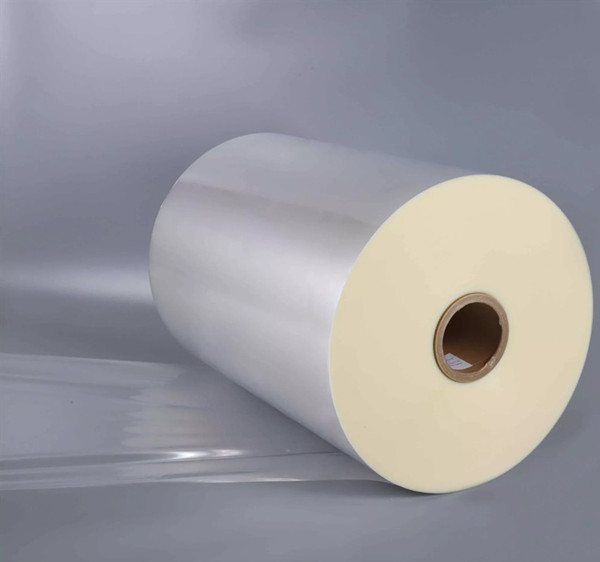

300AN is polyamide type of antistatic agent for plastic which has excellent performance in nylon polymer and alloys, especially for blown film. Its main features are high melting point and low addition amount. It can be dry-mixed and directly blown into film. It is recommended to add 10% to reach 10^10 ohm on condition 2.0 mils single layer film,It will be simi-transparency using nylon polymer of DSM F136 C1.

300AN main technical datas:

Density

1.09 g/cm³

Melting Point

190 °C

Shore Hardness A

95

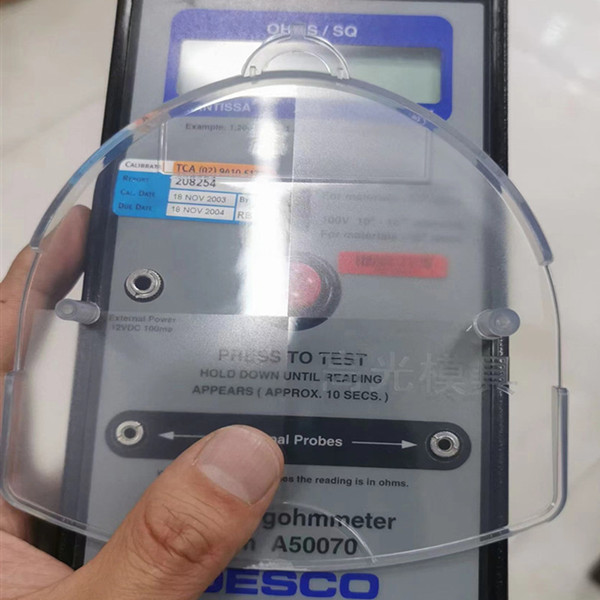

Surface Resistivity (25°C, 50%R.H)

1.7×10E6 Ohms

Thorough discussion of Non-Permanent antistatic agent

Most Non-Permanent antistatic agent for plastic is low molecular weight chemical with non-polar chains and polar hydrophilic heads.

It migrates to the surface of the material and reduces surface resistance by attracting water and dissipating electrostatic charges,but it requires ambient humidity to be effective ,it attract water humity from atmosphere.

Non-Permanent antistatic agent for plastic requires time to migrate and impart antistatic properties;

Over time, the agent is wiped off the surface of the material,cause he agent only covers the surface; it has no permanent effect and the static charge reappears.

Why should you choose INCHR

INCHR was established in Dongguan,China,manufactures a wide range of agents and polymers including antistatic agent for plastics and conductive materbatch,EMI shielding materials,It is a registered National Hi-Tech Enterprise and certificate of ISO9001,ISO14001.

INCHR works to satisfy the needs of its customers and we excel in speed and flexibility.We have long-term business relationships with customers who own typical partners such as Foxconn,Samsung,SK,BYD,GREE, Xiaomi, OFILM, FUJI XEROX, etc.As a leading manufacturer in ESD plastic industry, INCHR is growing tremendously. We are willing to provide quality products and services for more customers in various industries,including semi-conductor,chip equipment,consumer electronics, automotive, aerospace, etc.

In the future, we will continue to meet the challenge, grow the INCHR brand, and strive to become a world-class technology leader in new materials for all of our manufacturing processes.

Pre:POM ConcentrateNext:ABS Concentrate